9 Tips for Choosing Aluminum Cases

Aluminum alloy tool case is made of high-quality aluminum alloy profiles. It has the characteristics of reasonable design, solid structure and beautiful appearance. It is widely used in instruments, meters, electronics, communications, automation, sensors, smart cards, industrial control, precision machinery and other industries.

The ideal case for high-end instruments and meters is a kind of case that is formed by aluminum alloy material and can be used to place tools and measuring tools. Different from other tool cases, this tool case has the characteristics of aluminum alloy materials. It is easy to process and has incomparable advantages of other materials in terms of resistance strength.

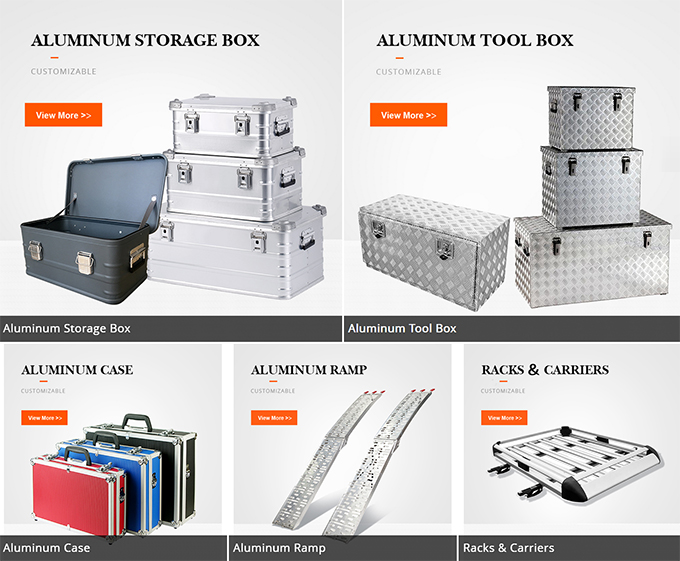

The series of products include: aluminum case, aluminum alloy tool case, aluminum alloy packing case, medicine case, display case and other aluminum product packing case manufacturers, aerospace case factory products include: jewelry case, CD case , chip case, document password case, beauty salon case, medical care case, precision instrument case, laptop computer case, clock case, tool case, aviation case, photographic equipment case, performance prop case, musical instrument case, billiard club case, golf suit case , Bank cash cases, banknote cases, barbecue cases, wine cases, fishing gear cases, gift cases, acrylic cases, various shockproof liners, etc.

Aluminum cases are widely used in beauty salons, tool sets, jewelry watches, stages, instruments, meters, electronics, communications, automation, sensors, smart cards, industrial control, precision machinery and other industries. It is an ideal case for high-end instruments.

There are many kinds of aluminum alloy cases. The following describes how to choose aluminum cases.

The first point: look at aluminum

Good quality: all aluminum alloys are oxidized, the width of the edging aluminum is 35mm, and the thickness is about 2mm Bad quality: All aluminum alloy cases are not oxidized, and the width of the edging aluminum is 30mm and the thickness is about 1mm.

The second point: the platen process Good quality: The panel and the board are generally bonded with white latex, pressed for 12-10 hours, and will not foam or wrinkle under strong light. Bad quality: The panel and the wood are generally glued with yellow glue, without pressing, blistering and wrinkling under strong light

The third point: look at the shock-proof material Good quality: New cotton made of new materials, good elasticity, shockproof effect reaches II level, EAV cotton is mostly used. Bad quality: The sponge is made of EVA made of old materials, and the elasticity is not good, so pearl cotton and high foam are mostly used.

Fourth point: look at hardware accessories Good quality: all hardware parts are plated and ironed, with good workmanship strength, and the diameter of the hand is 10mm. Bad quality: hardware plating and ironing are mostly processed in workshops, the workmanship is poor, and 8MM products are used for drawing hands.

Point 5: Look at the planks Good quality: The thickness of the board is 12mm, and the 7-layer national standard plywood will not deform after being damp, with good strength and impact resistance. Bad quality: The thickness of the 9mm board is only about 7mm, the non-national standard 3-layer board, most of which are poplar boards, deformed and deteriorated after being damp, and the strength is not good. Not resistant to impact

Sixth point: look at the wheels Good quality: 4-inch large double-bearing polyester wheels are used, with a load of 150KG/piece or a reinforced performance with a load of 200KG/ or more. Bad quality: 3-inch small single-bearing PVC wheels are used, with a maximum load of 80KG/piece.

Seventh point: look at the bottom plate Good quality: choose 15mm or 18mm whole board Bad quality: choose 9mm or 12mm board

Eighth point: look at the distance of the pull stud Good quality: generally around 100-150mm Bad quality: generally above 200

The ninth point: after-sales service Good quality: After-sales service of regular manufacturers is lifetime maintenance, free warranty for more than 1 year Bad quality: home workshop production without after-sales service, quality problems cannot be solved

KASSICO, a leading aluminum products factory in Ningbo, China, Have 22 years' production experience in manufacturing custom aluminum storage boxes, truck tool boxes, aluminum tool case, aluminum ramp, car racks and carriers for outdoors, camping, overlanding, military, medical etc.

We supply full custom service, including developing OEM & ODM projects. Our company owns 15000m2 factory area and more than 200 sets of advanced manufacturing equipments, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging.