Aluminum flight cases are mainly packaging boxes for air transport, and then with the continuous development and progress of social science and technology, it has now expanded from packaging in the air transport industry to packaging in other transport industries, including road transport packaging, sea transport packaging, and railway transport. packaging, etc.

1. Function

With the development of global economic integration and the wide application of high-tech products, high-end packaging carriers are increasingly required. Traditional wooden boxes and iron boxes and other packaging products have poor mobility, inconvenient loading and unloading, and are not environmentally friendly. There are high-end products' requirements for packaging carriers, so on this basis, a new generation of packaging boxes - flight cases will be developed. The flight case provides more perfect packaging for high-tech products in terms of convenience, mobility, and reusability in transportation. Flight cases are widely used in precision instrument industry, exhibition industry, stage lighting industry, LED optoelectronic industry, military industry, medical equipment industry, multimedia audio-visual industry, etc.

2. Classification

The flight cases can be divided into wooden fireproof board flight cases, ABS flight cases, pure aluminum flight cases, stainless steel flight cases, vacuum aluminum flight cases, etc. . Meamwhile, the flight cases can be selected according to customer requirements, and can be made of a variety of materials. You can choose multi-layer plywood, ABS board, aluminum plate, stainless steel plate, hollow board and other materials, eliminating the need for the cost of the mold is reduced, and the traditional packaging box generally needs to open the mold, and multiple materials cannot be selected.

External structure of the flight cases: The case structure is composed of multi-layer plywood and PBS fireproof board, ABS, aluminum plate and stainless steel plate. All sides of the case structure are made of aluminum alloy profiles with a certain thickness and strength. The strong spherical wrapping angle is connected and fixed with the L-shaped aluminum alloy edge and plate, the bottom of the outer case is reinforced, and the polyurethane wheel or rubber wheel with strong bearing capacity and high wear resistance coefficient is selected at the same time. Product Features Install shock-proof partitions, and paste relatively soft EVA or IXPE shock-proof materials on the inside of the box and the partitions.

3. Product Features

The internal and external structure and materials of the flight case determine its fireproof, waterproof, shockproof, anti-corrosion and convenient maneuverability. Because of years of design experience, high-precision production equipment and excellent production technology, the flight case has many advantages, including diverse styles, beautiful box body, safety and reliability, convenient maneuverability, excellent sealing, high buffering, and strong firmness. It is widely used in air transportation, railway transportation, road transportation and sea transportation.

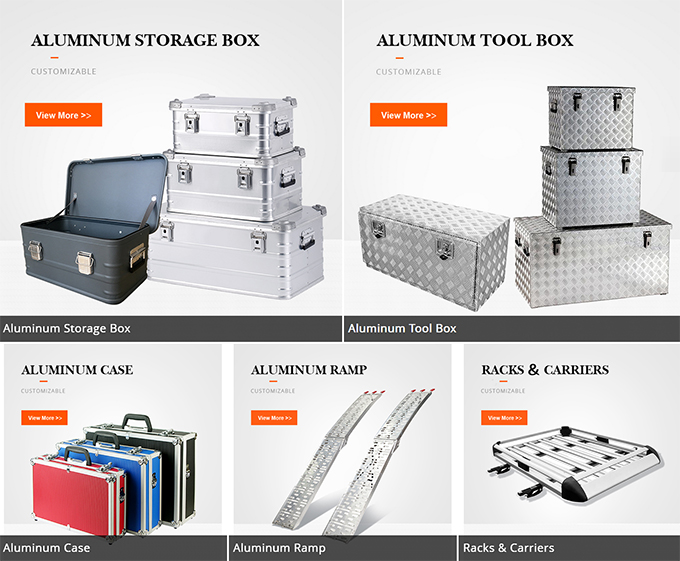

KASSICO, a leading aluminum products factory in Ningbo, China, Have 22 years' production experience in manufacturing custom aluminum storage boxes, truck tool boxes, aluminum tool case, aluminum ramp, car racks and carriers for outdoors, camping, overlanding, military, medical etc.

We supply full custom service, including developing OEM & ODM projects. Our company owns 15000m2 factory area and more than 200 sets of advanced manufacturing equipments, Perfect and rigorous QC system is implemented in every process from material purchasing to finished products packaging.